Please view our openings for up-to-date information

(Credit

for the work highlighted here goes to our entire team of very talented current and

past graduate students and postdoctoral fellows!)

Research

goal

The main goal of our research program is to help

maintain and improve health by providing medical doctors, biomedical

researchers and/or patients with novel

microelectronic technologies for miniature medical devices that directly or

indirectly interface with the human body in order to monitor its

function and, in some cases, influence it. We also target scientific,

industrial, consumer and environmental sensory electronics applications.

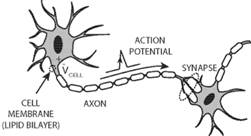

Motivation

Modern healthcare practices suggest that

patient-interfacing medical devices of the future are to be potent, ubiquitous,

and inexpensive. Our research investigates such medical devices. These devices

address specific unmet healthcare needs, particularly those in medical monitoring, diagnostics and therapy

in clinics, biomedical research labs and at home. Of our immediate interest are

applications in neuroscience and molecular biology.

We target disorders and diseases with limited conventional treatment options or

with costly diagnostics options. Specific medical applications include

electronic therapy for intractable epilepsy [J21, C51, C56, J13] and electronic screening

for early detection of certain types of cancer [C45, C50, J16, J27, J28, J11, J15, J24].

Approach

Interfacing with the human body for the purpose of

maintaining or improving health requires a variety of sensory functionalities.

These can be as simple as monitoring key vital signs, or as complex as

monitoring electrochemical activity of the brain or examining biochemical

content of bodily fluids. In our research we target applications

where novel implantable, wearable or disposable biomedical devices with complex

sensory functions are uniquely enabled by low-cost integrated circuit (IC)

technologies such as CMOS.

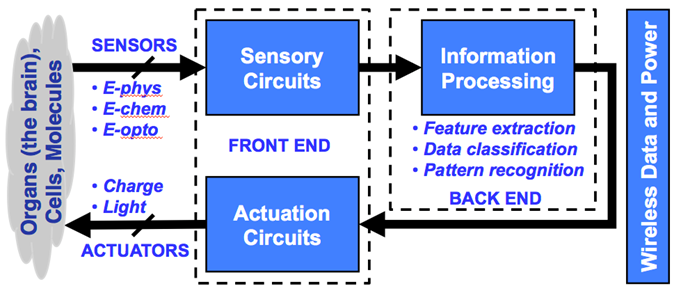

Specifically, we focus on the design of integrated

circuits, VLSI architectures and signal-processing algorithms that comprise the

core of a sensory medical device. Such

sensory devices not only acquire raw sensory data, but also perform local

sensory signal processing (such as feature extraction and machine learning data

classification algorithms), and provide feedback information or, in some cases,

feedback action as shown in Figure 1. One successful example of such a system

is a single-chip brain implant for treatment of intractable epilepsy we

developed that accurately detects early seizures and automatically triggers

neuro-stimulation to effectively control them [J21, C51, C56].

Figure 1. Functional block diagram of a biomedical

sensory microsystem (left) and an illustration of its form factor (right).

Key

challenges / RESEARCH DIRECTIONS

1. Sensor/Actuator Fabrication and

Microsystem Integration

From the sensor/actuator

fabrication and microsystem integration perspective, for potency,

ubiquity and low cost it is often advantageous to utilize sensory properties of

either the integrated circuits themselves or of additional small sensors with a

similar form factor. This approach avoids bulky externally connected sensors or

associated packaging costs. In our previous work, we have demonstrated

suitability of silicon integrated

circuits (ICs) to be further (post-CMOS)

integrated with various arrays of on-die and off-die sensors for

implantable, wearable and disposable microsystems implementations.

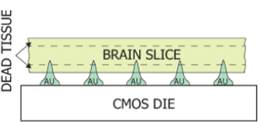

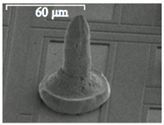

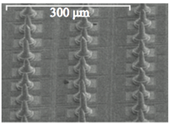

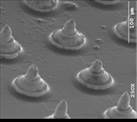

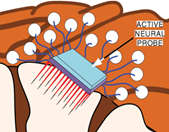

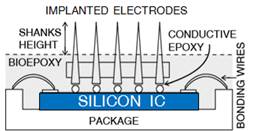

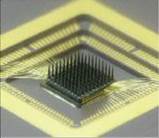

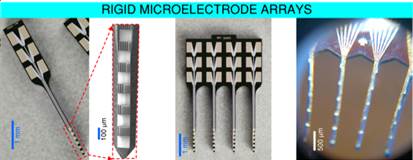

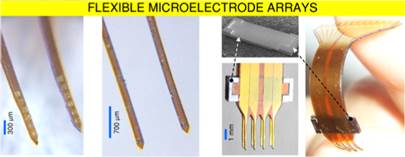

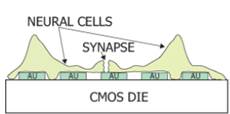

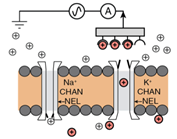

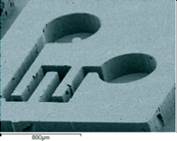

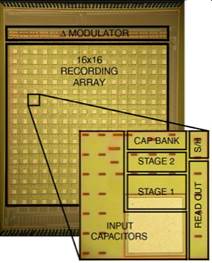

1.1 In electrophysiological sensing/actuation

applications, we have developed various such prototypes

including: arrays of gold micro-needles to monitor spatial maps of electrical

neural activity in the brain for in vitro epileptic seizure propagation studies

[J9,

C27, J26, J7,

J12, J25] (Fig. 2a, with Prof. Peter

Carlen), active neural probes comprised of 2D arrays of platinum micro-needles

directly co-integrated with neural amplifiers on an integrated circuit (Fig.

2b, with Prof. Peter Carlen), and 3D arrays of both rigid and flexible

microelectrodes for in vivo implantation (Fig. 2c, with Prof. Raafat Mansour

and Dr. Salam Gabran).

(a)

(b)

(c)

Figure 2. Examples of sensor fabrication and

microsystem integration techniques for electrophysiological

sensing/actuation applications.

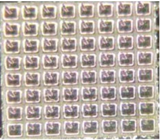

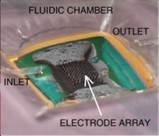

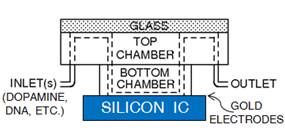

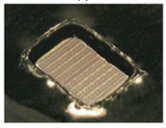

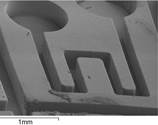

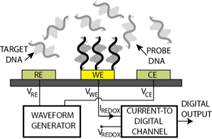

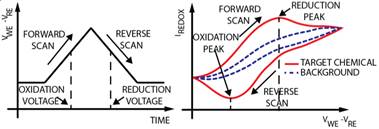

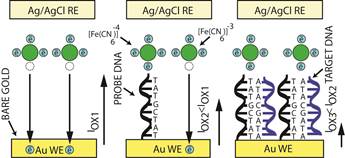

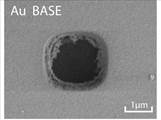

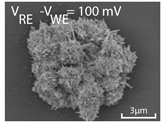

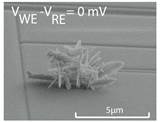

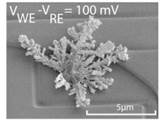

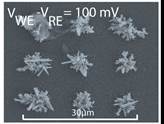

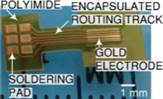

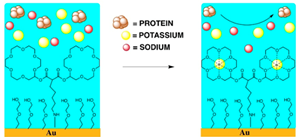

1.2 In electrochemical sensing/actuation

applications, the sensors prototyped by us range from arrays of

flat gold microelectrodes accessed by on-chip microfluidic structures (Fig. 3a,

with Prof. Guenther), to nanostructured gold electrodes with affinity-based

chemical functionalization (Fig. 3b; with Profs. Ted Sargent and Shana Kelley),

to post-implantation fouling-resistant on-gold chemical coating (Fig. 3c, with

Profs. Peter Carlen and Michael Thompson). Applications include molecular

diagnostics such as measuring pathogen DNA concentration and cancer screening

(Fig. 3b) [C45, C50, J16, J27, J28] and measurement of

concentration of neurochemicals for brain neurochemistry studies and

diagnostics [J35, J17, C37, J5]

(Fig. 3c).

(a)

(b)

(c)

Figure 3. Examples of sensor fabrication and

microsystem integration techniques for electrochemical

sensing/actuation applications.

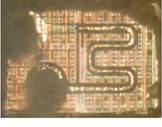

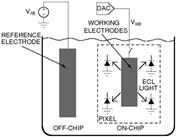

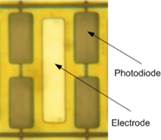

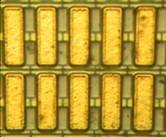

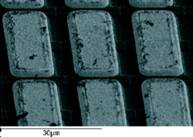

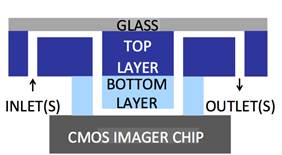

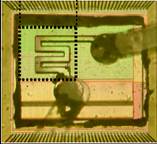

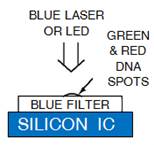

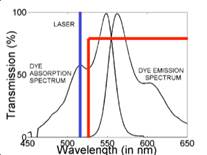

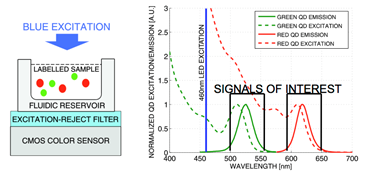

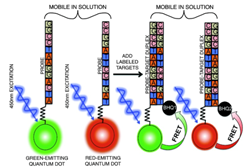

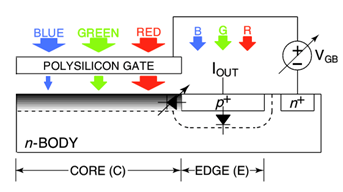

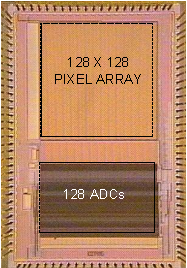

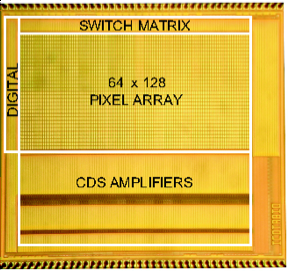

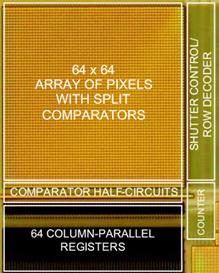

1.3 In electro-optical sensing/actuation

applications, we have

prototyped various CMOS imager sensors for both conventional non-contact and

emerging contact imaging applications. These include photo-detector arrays for

electro-chemi-luminescence (ECL) excitation and sensing (Fig. 4a) with fluidic

samples delivered through microfluidic structures (Fig. 4b, with Prof. Axel

Guenther) as well as single-color (Fig. 4c, with Prof. Glenn Gulak) and

multi-color (Fig. 4d, with Prof. Ulli Krull) fluorescence contact imagers.

Applications range from pesticide detection (Figs. 4a and 4b) to optical

imaging of various micro-scale biological objects such as fluorescently labeled

DNA microarrays (Figs. 4c and 4d) [J11, J15, J18, J23, J24].

(a)

(b)

(c)

(d)

Figure 4. Examples of sensor fabrication and

microsystem integration techniques for electro-optical

sensing/actuation applications.

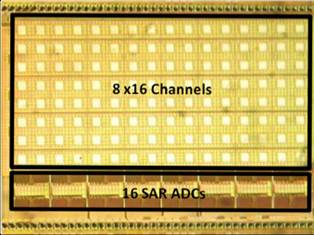

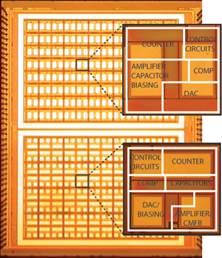

2. Front end: Sensory/Actuating

Circuits

From the front-end circuits perspective, the key

challenges are low signal-to-noise ratio, large sensory signal offset and

drift, high interference levels, intrinsic electronic noise, time-varying

signal source properties, various artifacts and numerous other sensory

interface-related issues. In our previous work, we have addressed these issues

individually by sensory transducer innovations

(e.g., novel photodetectors [J15,

J23]) and various integrated circuit design solutions (e.g.,

novel signal filtering circuits [J6, J20] and novel chopping circuits [J19, J23]). Our latest projects

include electro-physiological sensors for brain activity monitoring and

modulation (Fig. 5a), electro-chemical sensors for in vivo neurochemistry

monitoring and in situ molecular diagnostics (Fig. 5b), as well as optical

sensors for molecular detection, cellular imaging and computational photography

(Fig. 5c).

(a)

(b)

(c)

Figure 5. Examples of our sensory front-end

integrated circuits designs for (a) electro-physiological, (b) electro-chemical

and (c) opto-electronic sensory applications.

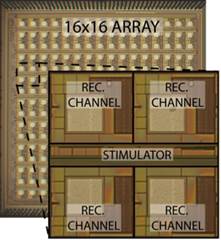

3. Back End: Computational Circuits

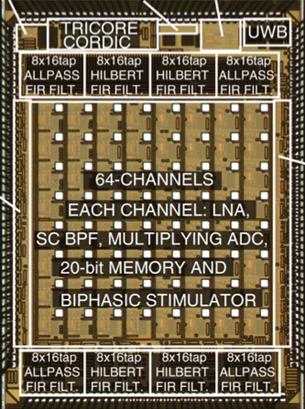

From the back-end circuits perspective, the key

challenges are the ever-growing requirements for intelligent ways to process

large amounts of sensory signal information (or big data), higher sensory data

processing throughput, and higher integration density with a limited power budget. The power budget is often constrained by heat

dissipation (such as that into the tissue surrounding an electronic implant).

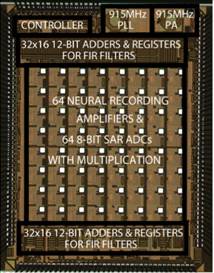

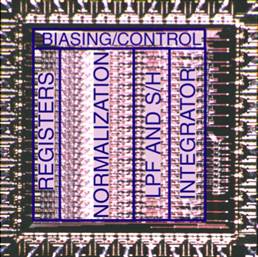

In our previous work, we have developed a number of circuit

design techniques that break the conflicting throughput-area-power trade-offs.

These include energy-efficient information-to-digital converter architectures

that perform computationally-expensive feature extraction and data

classification, such as in the application of triggering therapeutic

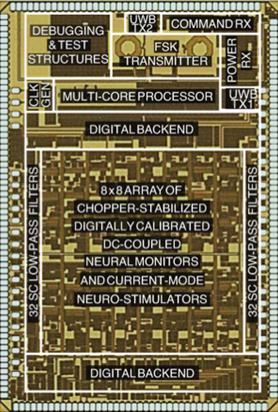

closed-loop neurostimulation (Fig. 6a) [J6,

J10,

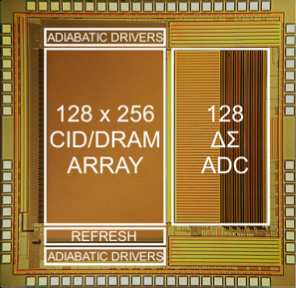

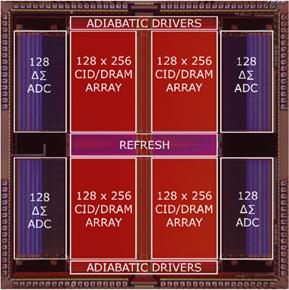

J16, J20], and energy-efficient

mixed-signal VLSI architectures for accelerating machine learning in sensory

data classification applications (Fig. 6b, with Prof. Gert

Cauwenberghs) [J8,

J13, J14, J20]. Within this thrust, we are

currently pursuing research on energy-efficient digital and mixed-signal VLSI

accelerators for high-performance machine learning and artificial intelligence

applications and computing architectures co-integrated with sensory arrays.

(a)

(b)

Figure 6. Examples of our computational back-end

integrated circuits: (a) mixed-signal multi-core DSPs within closed-loop

responsive neurostimulators for treating neurological disorders, and (b)

implantable mixed-signal machine learning accelerators (world’s first support

vector machines in silicon).

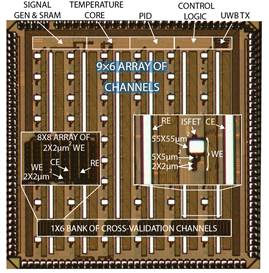

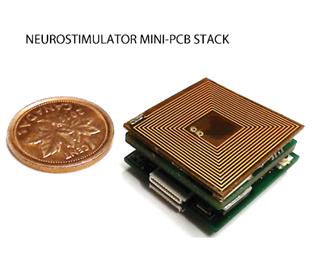

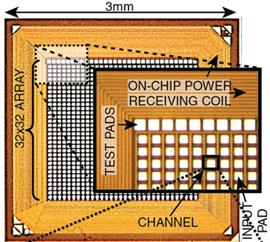

4. Wireless Communication and

Powering Circuits

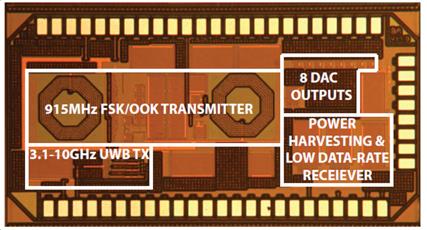

Sensory microsystems often require wire-free and

battery-free operation under strict constraints of low form factor, high data

rate, high energy efficiency and low specific absorption rate. Our solutions to

these challenges include low-power custom FSK and UWB radio-frequency

transceivers (Fig. 7a) [J20, J21, J27, C45, C50], as well as wireless energy

transfer circuits for neural recording and neurostimulation with off-chip (Fig

7b) and on-chip (Fig. 7c) RFID-type inductive power/data receiver coils [C55].

Figure

7. Examples of our RF transceivers and inductive energy transfer microsystems

prototypes: (left) custom radio-frequency transceivers, (middle) inductively

powered wireless neural recording and neurostimulation microsystem, and (right)

inductive power receiving circuits with an on-chip coil.

We

always look forward to having talented graduate students from the University of

Toronto and around the world join our team!